Cool Tips About Do People Still Use Modbus

فایل راه اندازی پروتکل مدباس (MODBUS) با Stm32 آموزش الکترونیک و نرم

Do People Still Use Modbus? You Might Be Surprised!

1. Is Modbus Still Relevant in Today's World?

Okay, let's talk Modbus. You might be thinking, "Modbus? Isn't that like, ancient history in the tech world?" Well, not exactly. While it's true that Modbus has been around for a while (we're talking decades!), it's still a surprisingly popular protocol in industrial automation. Think of it as the reliable old truck of industrial communication — not the flashiest, but it gets the job done.

Think about it: factories, power plants, and even some smart buildings are filled with equipment that needs to talk to each other. And that's where Modbus shines. It's a simple, robust, and relatively easy-to-implement communication protocol that allows different devices to exchange data. This isn't just some legacy system hanging on by a thread; it's actively being used in new deployments all the time. Modbus, in essence, offers a cost-effective means of integrating various systems.

But why? With all the fancy new communication protocols out there, why stick with something that's been around since, well, practically the stone age of networking? The answer is multi-layered, but it boils down to a few key things: cost, simplicity, and its established presence. Changing an entire industrial network to a brand-new system is expensive and can be very disruptive to operations. Modbus, therefore, represents a safe and familiar path for many organizations.

The continued relevance of Modbus stems from its ease of use, cost-effectiveness, and broad support across numerous industrial devices. Its simplicity allows for quick implementation, and the low overhead makes it suitable for resource-constrained devices. Plus, backwards compatibility is a huge plus. Upgrading bits and pieces of a bigger system doesn't necessarily mean scrapping everything.

The Strengths That Keep Modbus Going Strong

2. What Makes Modbus So Enduring?

Let's dive a little deeper into the reasons why Modbus is still kicking around. First and foremost, it's open and royalty-free. Anyone can use it without paying licensing fees, which is a big draw, especially for smaller companies or projects with tight budgets. It's also incredibly simple to understand, which makes it easier for engineers and technicians to troubleshoot and maintain systems. No complicated layers of abstraction or proprietary encryption to deal with.

Another significant advantage is its widespread adoption. Because Modbus has been around for so long, there are tons of devices that support it. This interoperability means you can mix and match equipment from different manufacturers without having to worry about compatibility issues. This is a huge benefit in industrial settings, where you often have a variety of equipment from different vendors working together.

And then there's the reliability factor. Modbus is a robust protocol that can handle the harsh environments often found in industrial settings. It's designed to be resilient to noise and interference, which are common in factories and other industrial environments. It might not be the fastest protocol out there, but it's dependable, and in many industrial applications, reliability is more important than speed.

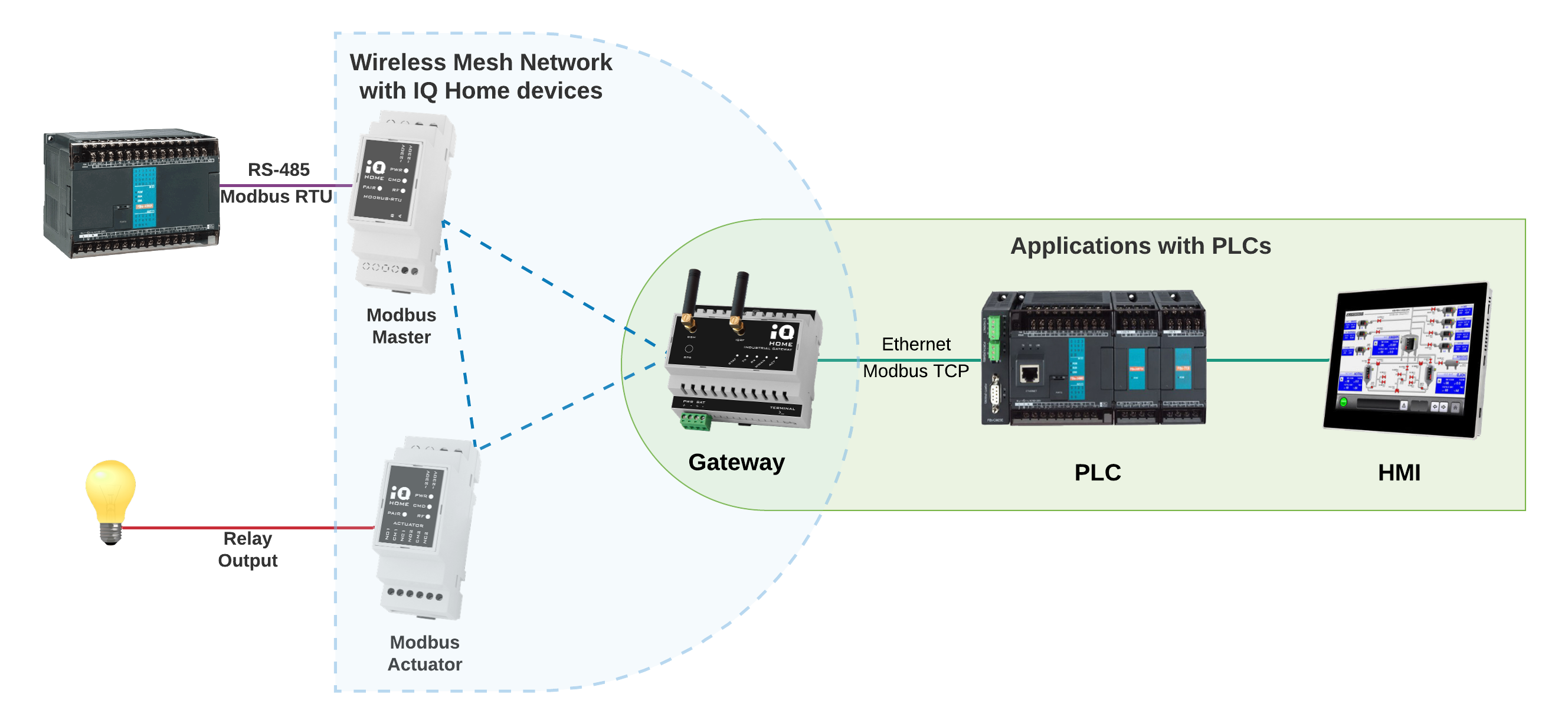

Modbus implementations exist across various mediums, including serial lines (RS-232, RS-485), Ethernet (Modbus TCP), and even radio frequencies. This versatility allows Modbus to be used in a wide range of applications, from simple sensor monitoring to complex control systems. Its adaptability has ensured its continued relevance in the face of evolving technologies.

Where You'll Still Find Modbus Today

3. Real-World Applications of Modbus in the 21st Century

So, where exactly is Modbus being used these days? Well, you'll find it in a wide variety of industries and applications. One common area is building automation, where it's used to control things like HVAC systems, lighting, and security systems. It's also widely used in manufacturing, where it's used to monitor and control machines, robots, and other industrial equipment. Imagine a factory floor: odds are, Modbus is involved somehow.

Another important application is in the energy sector. Modbus is used in power plants, oil and gas refineries, and renewable energy systems to monitor and control various processes. For example, it might be used to monitor the output of solar panels or to control the flow of gas in a pipeline. Its also frequently found in SCADA (Supervisory Control and Data Acquisition) systems, which are used to control and monitor large-scale industrial processes.

Think of your smart home. While you may not directly interact with Modbus there, chances are that some of the underlying systems, like your smart thermostat or lighting controls, are using it to communicate. Its simplicity and ease of integration make it a natural choice for these kinds of applications. It provides a standardised way to connect different devices, regardless of their manufacturer.

The applications extend to water and wastewater treatment plants, transportation systems, and even research laboratories. Anywhere you have a collection of sensors, actuators, and controllers needing to communicate, Modbus is likely in the running as a viable option. Its flexibility and adaptability have ensured its presence across diverse industrial landscapes.

The Future of Modbus

4. How Modbus is Evolving to Stay Relevant

While Modbus has proven its staying power, it's not without its limitations. One of the biggest challenges is security. The original Modbus protocol wasn't designed with security in mind, which makes it vulnerable to cyberattacks. Fortunately, there are now newer versions of Modbus that incorporate security features, such as encryption and authentication. These advancements will help Modbus remain relevant in an increasingly connected world.

Another area where Modbus is evolving is in its integration with other technologies, such as the Internet of Things (IoT) and cloud computing. Modbus TCP, which runs over Ethernet, is increasingly being used to connect industrial devices to the internet, allowing for remote monitoring and control. This integration allows users to collect data from their equipment and analyze it in the cloud, which can help them improve efficiency and optimize their operations.

Additionally, there are ongoing efforts to develop new extensions and profiles for Modbus to address specific application needs. These extensions are designed to improve the performance and functionality of Modbus in areas such as process automation and building management. It's a constant process of adaptation to maintain its position.

Looking ahead, Modbus is likely to remain a popular choice for industrial communication for many years to come. Its simplicity, cost-effectiveness, and widespread adoption make it a compelling option for a wide range of applications. Even as newer protocols emerge, Modbus will continue to evolve and adapt, ensuring its continued relevance in the ever-changing world of industrial automation.

Modbus vs. The New Kids

5. A Comparison with Modern Industrial Protocols

Okay, so you know Modbus is still around, but how does it stack up against newer, shinier protocols like Profinet, EtherCAT, or even MQTT? That's the million-dollar question, isn't it? Well, its not a simple answer. These newer protocols often offer higher speeds and advanced features like real-time communication and deterministic performance, which are essential for some applications. However, they also tend to be more complex and expensive to implement.

The choice often comes down to a trade-off between performance, cost, and complexity. For applications where speed and real-time performance are critical, a newer protocol might be a better choice. But for many applications where those factors aren't as critical, Modbus still offers a compelling solution. It's like choosing between a sports car and a pickup truck: it depends on what you need to haul and where you need to go.

Think of it this way: Modbus is like the "old reliable" that doesn't need all the bells and whistles. It excels in scenarios where ease of deployment and cost-effectiveness are paramount. The newer protocols often require specialized hardware and software, as well as significant training for engineers and technicians. Modbus, on the other hand, can be implemented with minimal investment and training. That's a big win for many organizations, particularly smaller ones.

Ultimately, the best protocol depends on the specific requirements of the application. There is no one-size-fits-all solution. While Modbus might not be the best choice for every situation, it remains a viable and practical option for many industrial automation applications, particularly when simplicity, cost, and widespread compatibility are key considerations.

Modbus Implementation On LAN. Download Scientific Diagram

Frequently Asked Questions (FAQs)

6. Your Modbus Questions Answered

Q: Is Modbus obsolete?A: No, Modbus is not obsolete. It's still widely used in various industries due to its simplicity, cost-effectiveness, and broad compatibility. While newer protocols offer advanced features, Modbus remains a practical choice for many applications.

Q: What are the main advantages of using Modbus?A: The main advantages include its open and royalty-free nature, simplicity, widespread adoption, robustness, and versatility in terms of communication mediums.

Q: What are the security concerns with Modbus, and how are they being addressed?A: The original Modbus protocol wasn't designed with security in mind, making it vulnerable to cyberattacks. However, newer versions of Modbus incorporate security features like encryption and authentication to mitigate these risks. Using secure implementations and network configurations can also enhance Modbus security.