Top Notch Info About What Is The Purpose Of Splicing Wires

Why Bother Splicing Wires? Let's Get Connected!

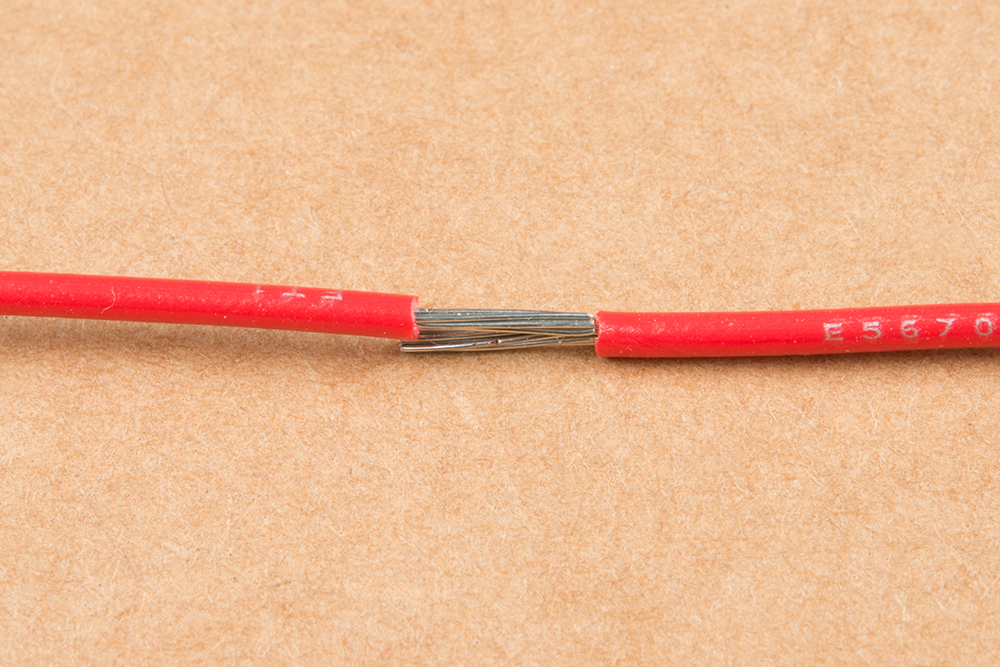

1. Understanding the Basics of Wire Splicing

Ever wondered why electricians spend so much time twisting bits of metal together? Well, that's wire splicing in action! Simply put, the purpose of splicing wires is to create a reliable and safe electrical connection between two or more wires. Think of it like joining two pieces of rope to make a longer one, but instead of rope, we're dealing with electricity — which, as we all know, needs to be handled with a bit more finesse. No one wants a light switch that works sometimes, and sets the drapes ablaze the rest of the time.

Splicing isn't just about making a wire longer, though that's certainly a common reason. It's about ensuring that electricity can flow smoothly and efficiently from one point to another. A poorly executed splice can lead to all sorts of problems, from flickering lights and malfunctioning appliances to, in the worst-case scenario, electrical fires. And trust me, dealing with the aftermath of an electrical fire is nobody's idea of a good time.

So, when might you need to whip out your wire strippers and get splicing? Plenty of times! Maybe you're extending the wiring for a new light fixture, repairing a damaged wire, or connecting different sections of an electrical circuit. Whatever the reason, understanding the principles of wire splicing is essential for any DIY enthusiast or aspiring electrician. It's like learning to tie your shoelaces — a fundamental skill that will serve you well throughout your life (though hopefully with fewer embarrassing stumbles).

The "splicing wires" part, the core of all this, as a noun refers to the act of joining these conductive strands. It's the procedure itself, the method by which you're creating a continuous pathway for electricity. Now, you might be thinking, "Why not just use one long wire?" Sometimes that's not practical, feasible, or even possible! You might only have shorter lengths available, or you might need to create a branch in the circuit. That's where splicing really shines, as an action.

Splicing 18 Gauge Wire

Making the Connection

2. Exploring Various Wire Splicing Methods

There's more than one way to skin a cat, as they say, and there's also more than one way to splice a wire! Different situations call for different techniques, each with its own set of advantages and disadvantages. Some common splicing methods include the Western Union splice, the pigtail splice, and the tap splice. Don't worry, you don't need to memorize all the names — just understand the basic principles behind each method.

The Western Union splice, for example, is a strong and reliable method often used for joining solid wires. It involves twisting the wires together tightly and then soldering the connection for added strength and conductivity. The pigtail splice, on the other hand, is a simpler method that's typically used for joining multiple wires together in a junction box. It's quick and easy, but it may not be as strong or durable as the Western Union splice.

And then there's the tap splice, which is used to connect a new wire to an existing wire without cutting the existing wire. This is particularly useful when you need to add a new circuit or device to an existing electrical system. Each method requires precision, attention to detail, and the right tools. Trying to splice wires with your bare hands and a pair of dull scissors? Not recommended (unless you're auditioning for a role in a slapstick comedy).

When choosing a splicing technique, consider factors such as the type of wire you're working with (solid or stranded), the size of the wire, and the location of the splice. Also, make sure to follow all applicable electrical codes and safety regulations. Messing with electricity can be dangerous, so it's always better to be safe than sorry. Wear appropriate safety gear, like insulated gloves and safety glasses, and never work on live wires. Unless, of course, your super power is immunity to electrical shocks.

Different Types Of Wire Splices » Wiring Flow Line

Tools of the Trade

3. Essential Tools for Safe and Effective Splicing

You wouldn't try to build a house with just a hammer and a rusty nail, would you? Similarly, you'll need the right tools to splice wires properly. Some essential tools for wire splicing include wire strippers, wire cutters, pliers, and electrical tape. Wire strippers are used to remove the insulation from the wires without damaging the underlying conductor. Wire cutters are used to cut the wires to the desired length. Pliers are used to twist the wires together and to crimp connectors.

And then there's electrical tape, which is used to insulate the splice and protect it from moisture and corrosion. Always use high-quality electrical tape that's specifically designed for electrical applications. Don't be tempted to use duct tape or masking tape — they're not designed for electrical use and can pose a safety hazard.

In addition to these basic tools, you may also need a soldering iron and solder if you're planning to solder your splices. Soldering creates a strong and reliable electrical connection, but it requires some skill and practice. If you're not comfortable soldering, you can use crimp connectors instead. Crimp connectors are easy to use and provide a secure connection without the need for soldering.

Investing in good-quality tools will make the job easier and safer. Cheap, poorly made tools can be dangerous and can damage the wires, leading to unreliable connections. Think of it like buying a good pair of shoes — they may cost a bit more upfront, but they'll last longer and provide better support (both literally and figuratively).

Safety First! Essential Precautions When Splicing Wires

4. Prioritizing Safety in Electrical Work

Electricity is a powerful force, and it should always be treated with respect. When working with electricity, safety should be your top priority. Before you even think about picking up a wire stripper, make sure to turn off the power to the circuit you'll be working on. This is absolutely crucial to prevent electric shock.

Double-check that the power is off by using a non-contact voltage tester. These handy devices can detect the presence of electricity without you having to touch the wires. If the tester indicates that the power is still on, don't proceed. Find the correct circuit breaker and turn it off. It's like performing surgery — you wouldn't want to operate on the wrong patient (or the wrong circuit, in this case).

Wear appropriate safety gear, such as insulated gloves and safety glasses. Insulated gloves will protect you from electric shock, while safety glasses will protect your eyes from flying debris. Also, make sure to work in a well-lit area and avoid working in wet or damp conditions. Water and electricity don't mix! It cant be overstated!

Finally, if you're not comfortable working with electricity, don't hesitate to call a qualified electrician. It's always better to be safe than sorry. A licensed electrician has the training and experience to handle electrical work safely and efficiently. Think of it like hiring a professional chef to cook a complicated meal — they'll get the job done right and you won't end up with a kitchen fire (or a blown fuse).

Solder Splice Atelieryuwa.ciao.jp

Ensuring a Solid Connection

5. Verifying the Quality of Your Work

So, you've spliced your wires, taped them up, and put everything back together. But how do you know if your splice is any good? The best way to find out is to test it! A simple visual inspection can reveal obvious problems, such as loose connections or exposed wires. Make sure the wires are securely twisted together and that the electrical tape is properly applied.

For a more thorough test, you can use a multimeter to check the continuity of the circuit. Continuity is a measure of how easily electricity can flow through a circuit. If the circuit has good continuity, it means that the splice is making a good electrical connection. If the circuit has poor continuity, it means that there's a problem with the splice.

You can also use a voltage tester to check for voltage drop across the splice. Voltage drop is a measure of how much voltage is lost as electricity flows through a circuit. A significant voltage drop across the splice indicates that the splice is not making a good electrical connection and may need to be redone.

Testing your splices is an important step in ensuring a safe and reliable electrical system. Don't skip this step! It's like proofreading a document before submitting it — you want to catch any errors before they cause problems. A well-tested splice will give you peace of mind knowing that your electrical connections are secure and reliable, and that you won't wake up to a flickering light or a sparking outlet.

Frequently Asked Questions (FAQs)

6. Answering Your Burning Questions About Wire Splicing

Here are a few frequently asked questions about splicing wires that might be buzzing around in your head:

Q: Can I splice wires of different gauges?A: It's generally best to avoid splicing wires of significantly different gauges. Using wires of different sizes in the same circuit can create a bottleneck and lead to overheating. If you must splice wires of different gauges, use a connector that's specifically designed for that purpose and make sure the connection is secure.

Q: What's the best way to insulate a wire splice?A: Electrical tape is the most common way to insulate a wire splice. Use high-quality electrical tape and wrap it tightly around the splice, overlapping each layer by at least half. You can also use heat-shrink tubing for a more durable and professional-looking insulation.

Q: Is it legal to splice wires myself?A: Electrical codes vary from place to place, so it's important to check your local regulations before doing any electrical work. In some areas, you may be required to have a permit or hire a licensed electrician for certain types of electrical work. It's always better to err on the side of caution and make sure you're following all applicable regulations. Ignorance is no excuse, especially when dealing with potentially dangerous stuff like electricity.